what are you looking for?

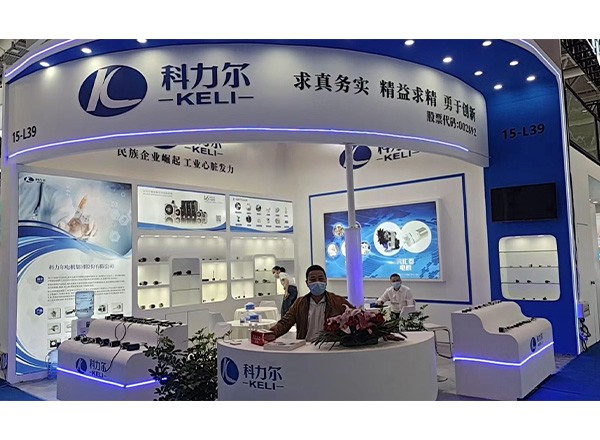

China International Medical Equipment Fair

China International Medical Equipment Fair

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

IPv6 network supported

IPv6 network supported